Inside MG's Halol Facility

MG Motor India's Halol facility is emerging as one of the country's advanced automotive plants, combining large-scale production with progressive workforce practices and forward-looking technology.

The plant currently operates with an annual production capacity of over 100,000 units, with further expansion on the horizon. Nationwide, the automaker supports its customer base through 550 touchpoints across 220 cities and employs more than 6,000 people. MG's dealer network was recently ranked No. 1 in the FADA "Creme de la Creme" Dealer Satisfaction Study, underscoring its focus on service quality.

A Diverse, Resolute Workforce

One of the most notable aspects of the Halol plant is its workforce composition. Women account for more than 45% of employees, rising to 60% in paint shops and going up to 85% in other key areas. The female workforce is not restricted to assembly line jobs; even supervisors and managers here are women, a few of whom took us on this tour of the facility, explaining each step with intricate details to us. To support this level of integration, all workstations have been ergonomically designed to suit employees of varying physical stature, reducing strain and improving efficiency.

The company has also launched MG Nurture, a collaboration with more than 25 engineering and technical colleges, to train and prepare the next generation of automotive professionals.

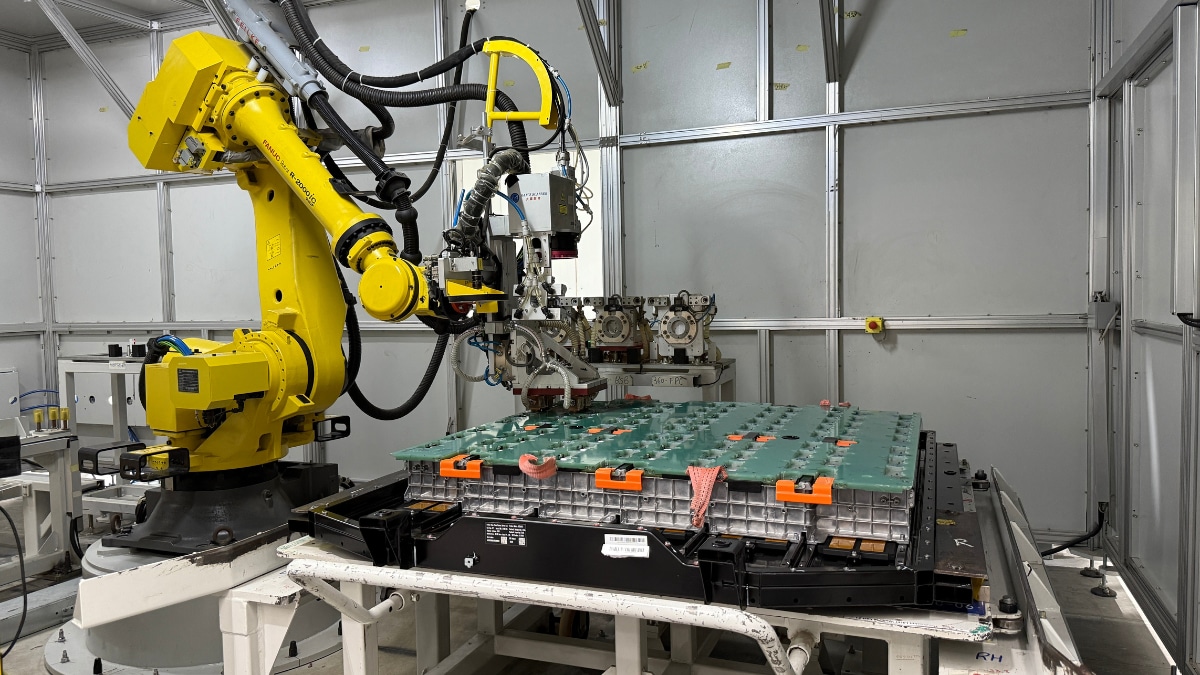

The Battery Facility

The facility's structured production system is divided into four lines:

Module Line: On the module line, the process begins with imported cells already screened and sorted by strength and resistance. The Windsor pack gets 98 of them; the Comet gets by with 36. They're small, about a kilogram each, but treated with almost surgical precision. The entire battery structure gets all its internal components brought together here.

Operators perform multiple tests, only after which the battery goes forward to the Pack Line. The Windsor modules even get coolant hardware built in before being labelled for traceability.

Pack Line: Next comes the pack line, and those modules start coming together. Bus bars are welded, and protective casings are sealed tight to IP67 standards. Multiple tests, along with leak tests, are also performed to keep everything perfect and in line with safety standards. From this moment on, the pack is considered high voltage. Operators suit up in protective gear, and every action is double-checked.

Charging & Discharging Line: With seven machines, each processing four batteries at a time in 3.5 hours, the plant can stock up to 250 batteries simultaneously. The process charges and discharges the battery to check the efficiency and quality of the battery, and only after passing through various other safety checks, is it then sent forward to the Final Line.

Final Line: The Final Line ties it all together. Logs of voltage, insulation, and torque; every number is checked against batch records. If something doesn't align, the pack is pulled apart and rebuilt. Nothing is left to chance, even the smallest inconsistencies are taken into consideration to produce a perfect battery fit to be part of the MG EV ecosystem.

Windsor EV Assembly

The Windsor EV battery reaches the main facility. The facility here has three lines: the Trim Line, the Chassis Line and the Final Line. Through an articulated network of automated conveyor belts, the car gets prepared to be rolled out. The body comes through the paint shop and gets the dash, infotainment, steering and seats installed. This follows through to the line where the battery is fitted along with the front and rear axles.

The usage of robots is at its maximum at this part of the facility. Robots follow a magnetic path to carry the battery and place it directly under the body of the car, which is then lifted and bolted into the base of the vehicle by engineers. However, MG's attitude towards the welfare of their workers is notable, as anything beyond 9 kgs is mechanically handled, keeping in mind the diverse workforce they employ. In an hour, the facility is capable of rolling out 15 Windsor EVs from scratch to slick.

Future of EV Manufacturing

From welding and initial assembly to final testing, MG's Halol facility demonstrates how automation and human expertise can complement each other. With its scale, efficiency, and inclusive workforce model, the plant positions MG Motor India not just as a manufacturer but as a forward-looking player in the evolving Indian auto industry.