Excellence in the making: How the all-new Creta takes shape

Over 6.6 lakh utterly satisfied customers all around the world and in just five years time; the made-in-India Hyundai Creta has racked up impressive numbers since its launch. And on the eve of its fifth year running, in comes an all-new Creta, more than well-equipped to continue the success story, and we get an all-access pass to see how it all comes together.

Quickly, is the first impression of it. In the time it's taken you to reach this point of the story, another Hyundai has rolled off the production line! Thanks to the 13,500-plus strong production workforce and 650 robots working in harmony, a car is made every 33 seconds, an unbelievable step up from the one car being made every four minutes when Hyundai first set up shop in India in 1996. From a single model then, to 12 currently, with over 350 variants, Hyundai India has made over nine million cars to date!

And there's no resting on laurels here. For example, with the all-new Creta, an entire station has been set up just to take care of assembly of the segment-leading smart panoramic sunroof from two sheets of metal. Entirely automated, this station is a shining example of the forward thinking that goes into every Hyundai, exemplified by the all-new Creta. In fact, when it comes to prototyping new parts, Hyundai was one of the earliest manufacturers to turn to 3D printing, the most ideal way to a quick turnaround that's revolutionised auto manufacturing worldwide. With R&D coming from Hyundai's 870-acre Namyang research centre in Korea, along with inputs from its two-lakh square foot facility in Hyderabad, the all-new Creta has been developed for India, and the world. The very manufacturing plant we visited exports cars to 88 countries around the world, and recently helped Hyundai to the milestone of being the quickest manufacturer to export three million cars. The fact that the plant runs like clockwork right around the clock, in three shifts and six days of the week, definitely has something to do with it!

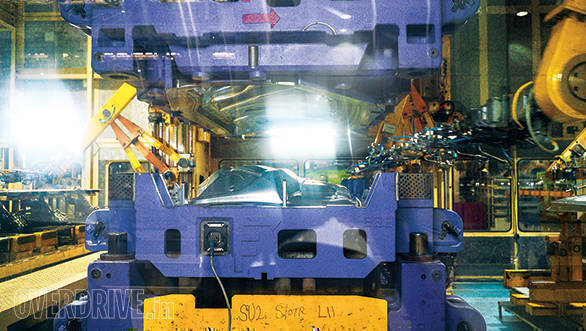

Of course, it all begins with a sheet of metal in the press shop. Sheets of metal, to be precise; over 540 acres of it. That's the amount of metal that's stamped every single day, sandwiched between precise colour-coded moulds for each model. Purple moulds signify the ones for the all-new Creta, and are the literal building blocks for an operation like this. Over 2,000 tonnes of stamping force help the bold fenders, hood, and other body panels of the all-new Creta take shape, being passed along the line to be neatly trimmed of excess metal, poked for other parts to fit in and then meticulously scrutinised by hand before being stacked, several hundreds high.

The all-new Creta, with 74.3 per cent of its body and structure in Advanced High Strength Steel (AHSS), benefits from an even stronger superstructure than before. Not to mention the advancements of 3D scanning and ultrasonic measurements to ensure millimetre perfection in every body panel, resulting in the kind of even panel fitment that impresses. Variations are not found often, and when they are, the panel doesn't make the cut, literally.

The body shop is where the individual pieces start to fit together, like pieces of a puzzle. With over 220 robots handling the entire line, it's like the largest scale mechanical ballet you've ever seen. Bare chassis move along the conveyor belt, as various panels are spot-welded into place, fitting into each other exactly at the right place. A full 100 per cent weld automation for the 4,500 welds per car means all of the strength and quality, 100 per cent of the time.

Hyundai uses big data from the 2,430 connected machines to be able to accurately predict a machine malfunction before it even happens! Which means there's an over 100 per cent reduction of downtime for replacing machinery on the production line, and again, cent per cent quality. Through three separate stages of quality confirmation, the shell of the all-new Creta makes its way to the paint shop.

By now, you start to get an understanding of the obsessive pursuit of perfection that goes into every Hyundai, and in this case, the all-new Creta. It's for that exact reason, and safety-wise, that the bare amount of human workforce is allowed into the paint shop, the next step in the process. Here, a pristine work environment and sealed chambers allow robots to dip the entire structure in anti-corrosion chemicals, while other robots apply coat after coat of sealants and glossy paint on the body-in-white. It explains why we can be sure that the lustrous and deep paint quality of the all-new Creta will remain even five years down the line, in much the same way that the paint finish of even the earliest Creta you see on the road has.

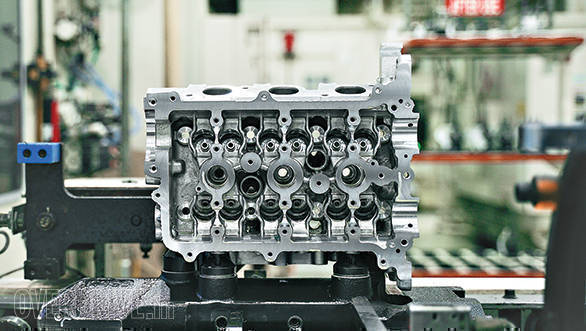

Similarly built to last are the range of engines on offer in the all-new Creta the new 1.5-litre diesel and petrol engines, and the sporty 1.4-litre turbocharged petrol, all of which are BSVI compliant. Of particular pride is the advanced 1.5-litre U2 CRDi engine manufactured here exclusively, with its variable geometry turbocharger, and clean burning exhaust catalyst systems. Over 1,700 moving parts come together in each engine, and Hyundai uses an environmentally friendly cold-start engine check process along with detailed robotic analysis to catch any flaws, an extreme rarity, as with other processes.

Finally, we get to the assembly of the all-new Creta. The last stage, it's where everything from the interiors to the glass areas to the mechanicals come together with the body. Painted body panels are either removed, or placed under protective covers while each station along the line adds another piece to the car. Again, humans and robots work together to ensure smooth continuity and exacting quality.

Here a series of quality checks are carried out, both automated and by hand, ranging from shower tests to check for any leaks, variations from standard and that all features work as intended, before each Creta is sent onto a road test track to ensure it functions as mechanically perfect as it should.

Hyundai does a pre-delivery inspection on every car, not just once, but twice. The first, at the factory, needs to be passed before the car is ready for delivery to showrooms, where the second PDI takes place. And of course, at the end of that inspection, the all-new Creta is ready to be driven home, and provide you with countless kilometres of blissful motoring.